Advanced NDT solutions for Aerospace & Railway — Reliable, Automated, Field-Proven

Designing and manufacturing robotics and NDT instruments for composite, metallic and rail inspection. Global service & training.

- 18,000 certified tests — proven reliability

- Industry solutions for Aerospace, Railway and more

- On-site training and full technical support

Our production

We deliver an extensive range of non-destructive testing equipment

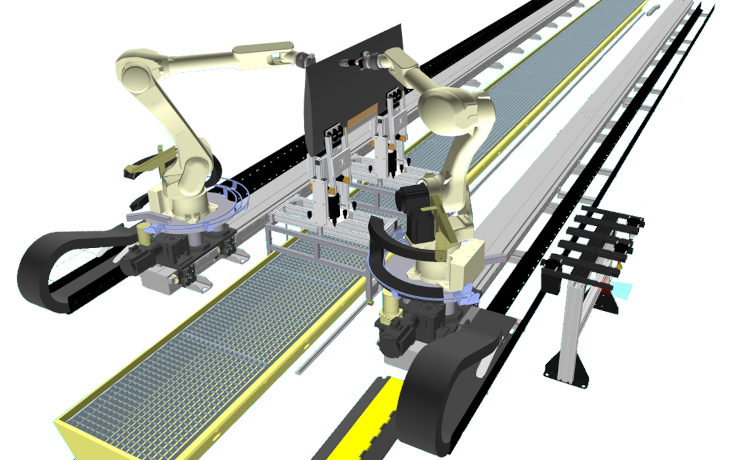

ROBOSKOP VTM-5000 AEROSPACE

The stend of laser scanning and flaw detection ROBOSKOP VTM-5000 AEROSPACE is designed for non-destructive testing of composite materials, honeycomb structures and heat-shielding coatings, used in the space industry.

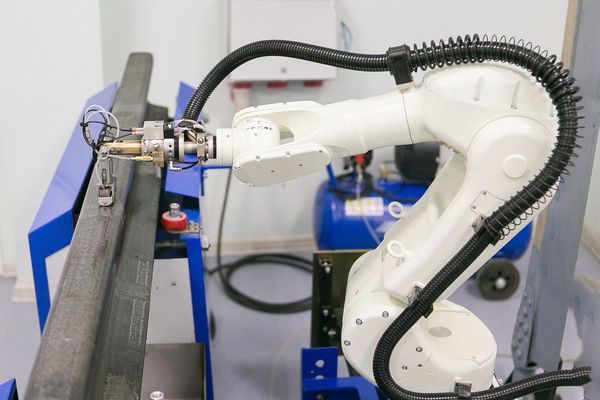

ROBOSKOP VTM-5000 HELICOPTERS

The laser scanning and flaw detection bench ROBOSCOP VTM-5000 HELICOPTERS is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels It is also applicable in wind power engineering, small-sized shipbuilding, pipe fitting production, etc. All tooling (laser scanner, sensors) selection and change processes are automated.

ROBOSKOP VTM-5000 СOMPOSITE

The laser scanning and flaw detection bench ROBOSCOP VTM-5000/COMPOZITE is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels It is also applicable in wind power engineering, small-sized shipbuilding, pipe fitting production, etc. All tooling (laser scanner, sensors) selection and change processes are automated.

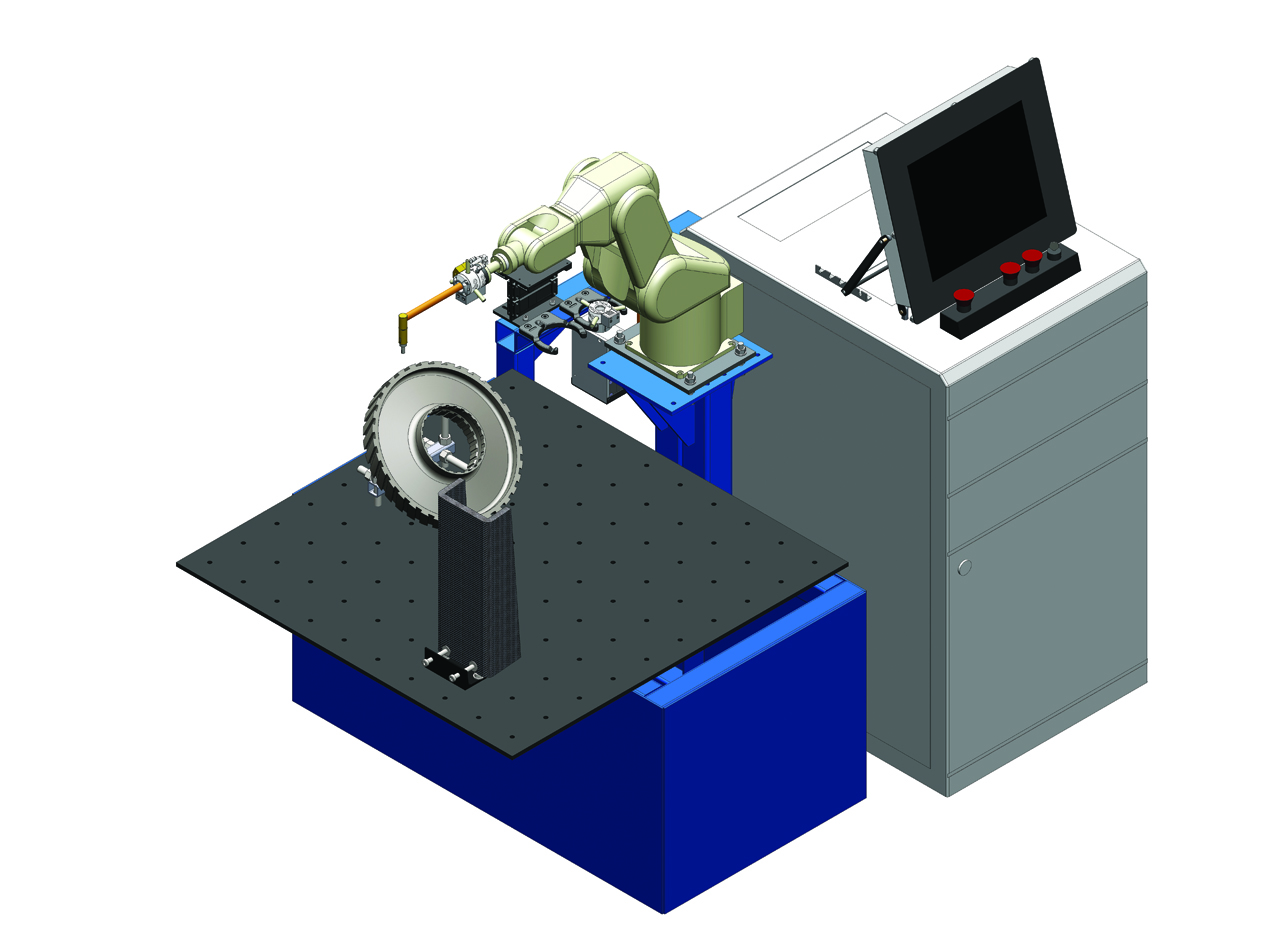

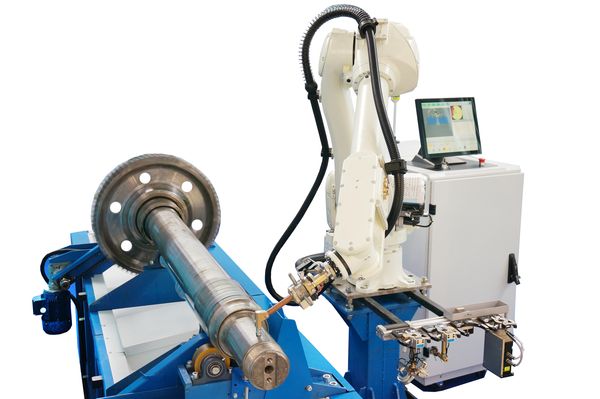

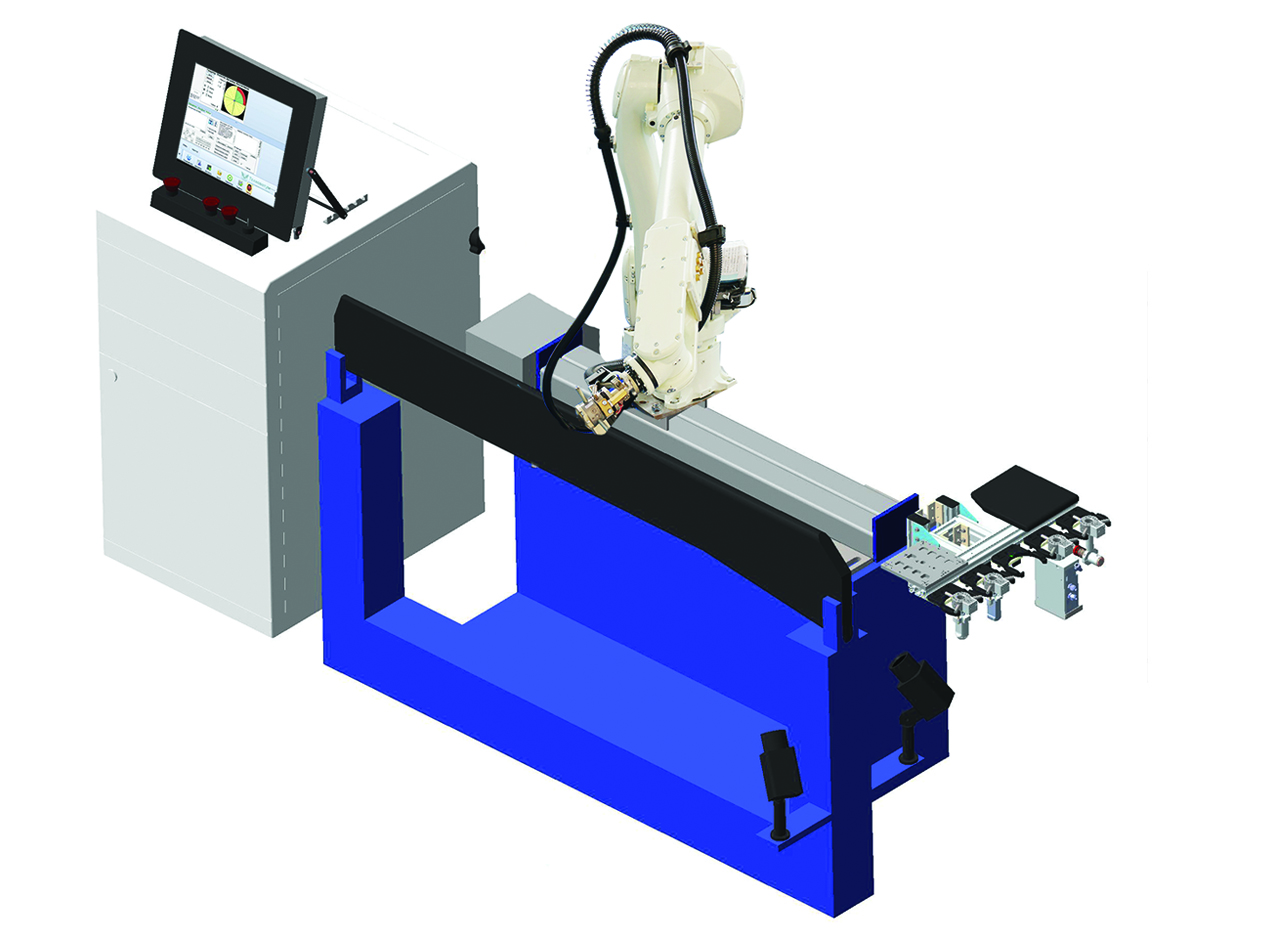

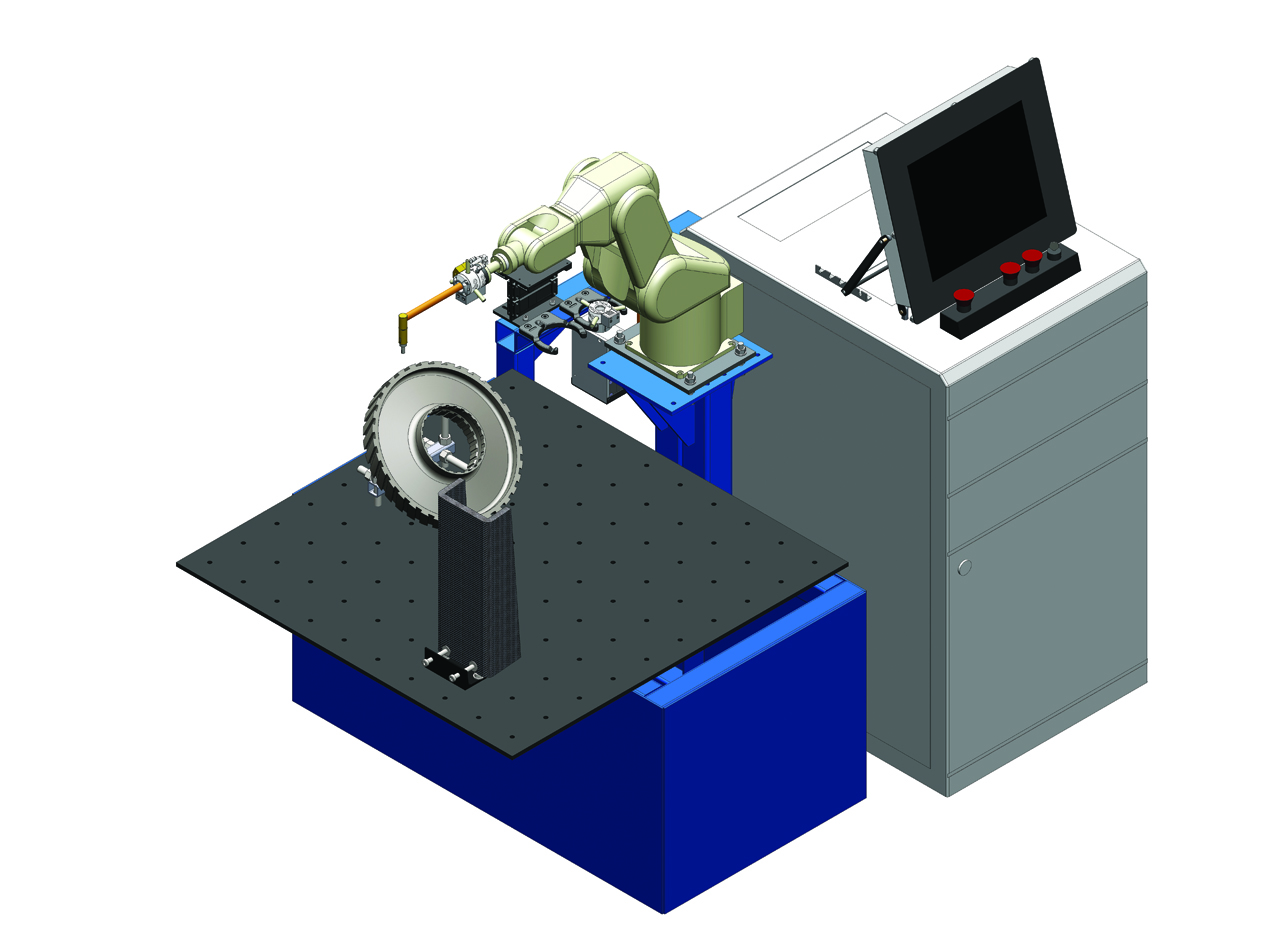

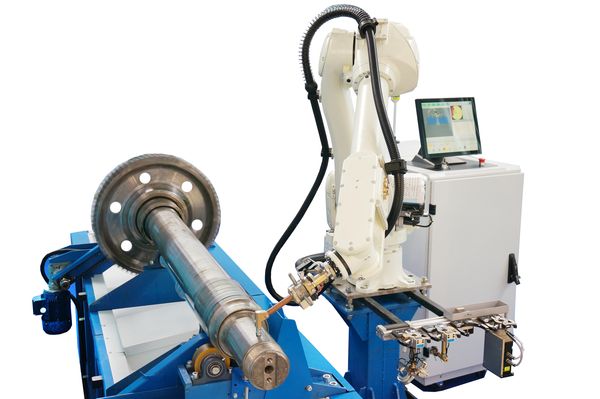

ROBOSKOP VTM-5000 DISK

The laser scanning and flaw detection equipment ROBOSKOP VTM-5000 / DISK is designed for non-destructive testing of aircraft engine parts of various range by type and size. Typical test objects are aircraft blades, discs, various shafts and workpieces. ROBOSKOP VTM-5000 / DISK automatically performs operations with high accuracy of testing results and low test time.

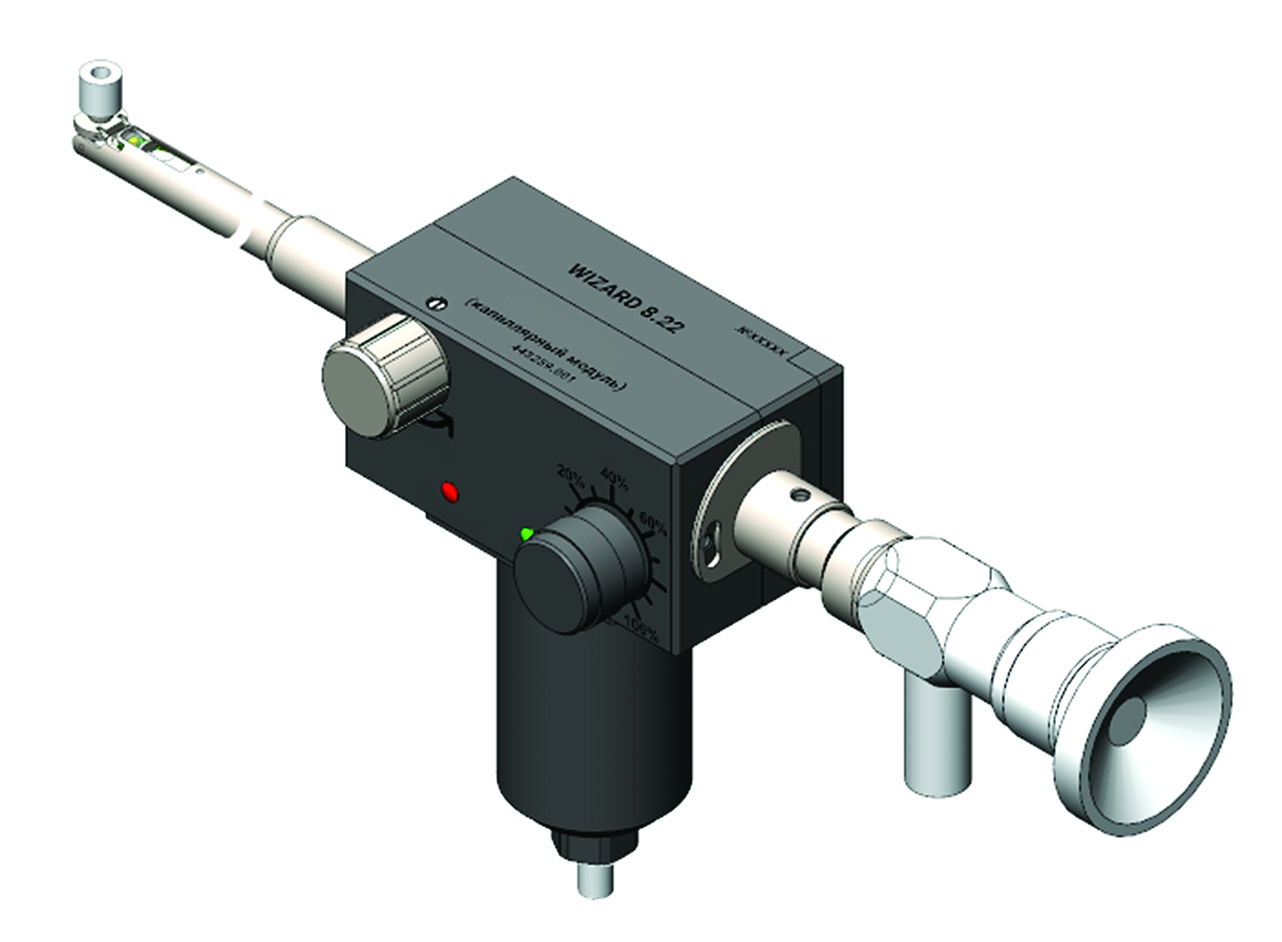

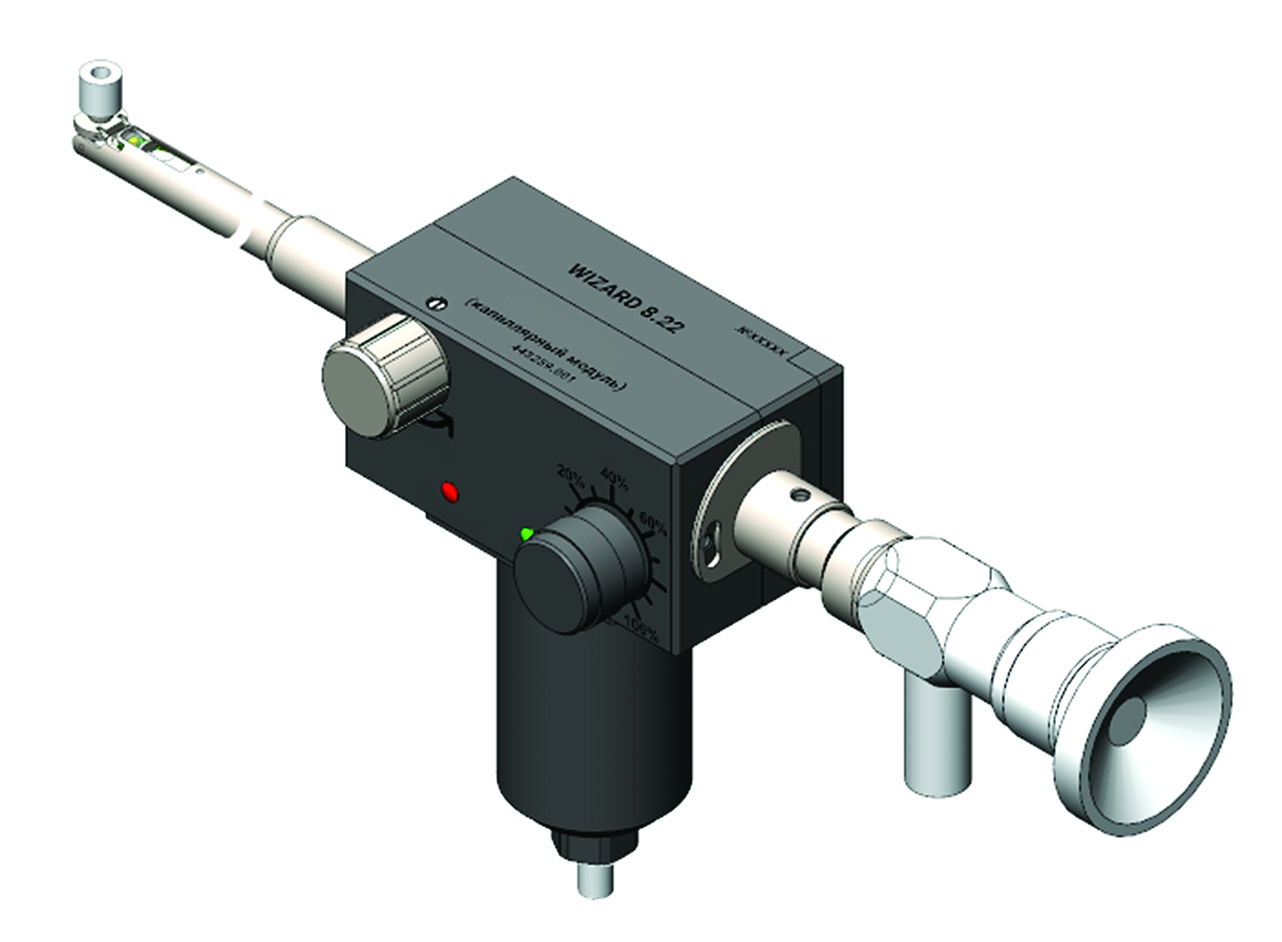

BLENDING SCOPE WIZARD

WIZARD - blending scope for diagnostics and machining blades os aircraft engines. Blending scope is a set of assemblies and modules for diagnostics and service of blades of the aircraft engines and gas turbines. Milling module + Liquid penetrant modules in one case for multitask applications.

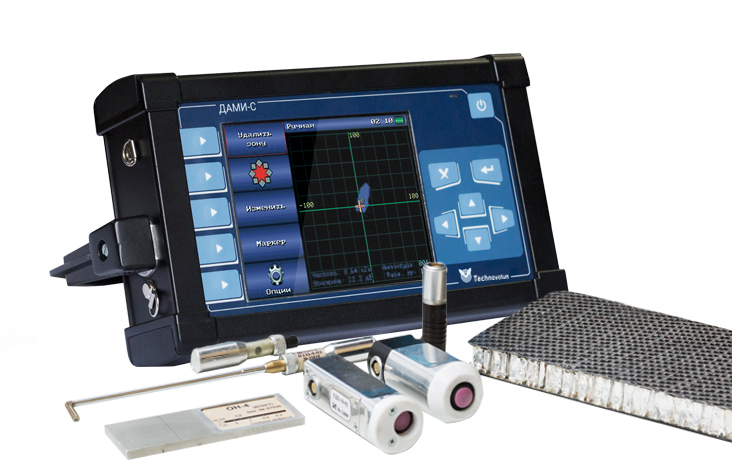

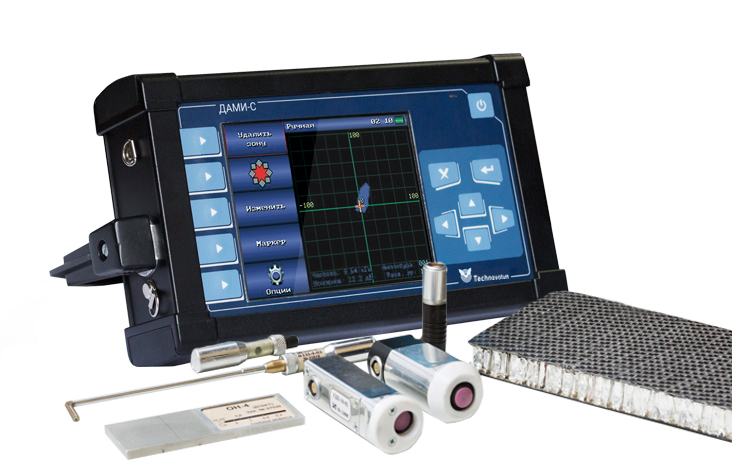

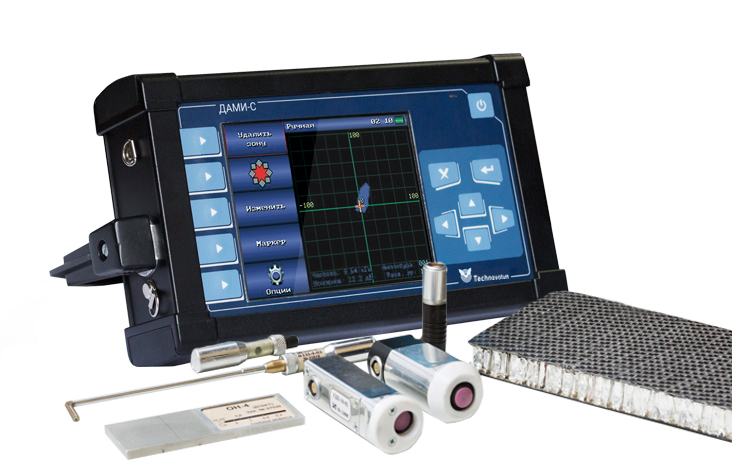

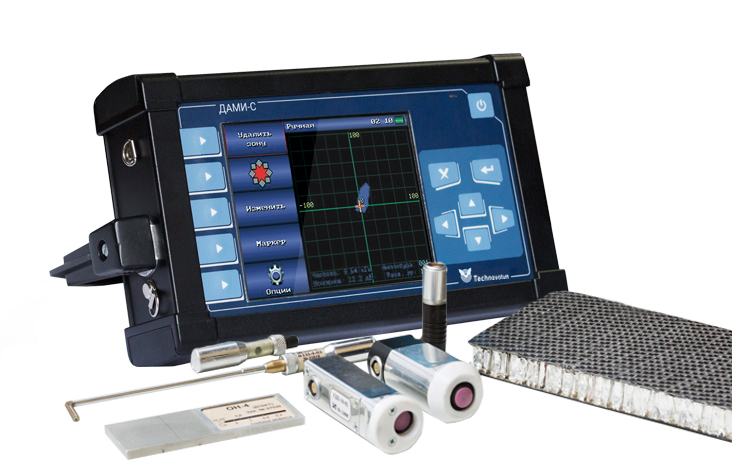

DAMI C-09

MECHANICAL IMPEDANCE ANALYSIS FLAW DETECTOR Is intended for detection of laminations, discontinuities, defects of lack-of-adhesion type and other continuity faults in multi-layer polymeric composite materials (PCM).

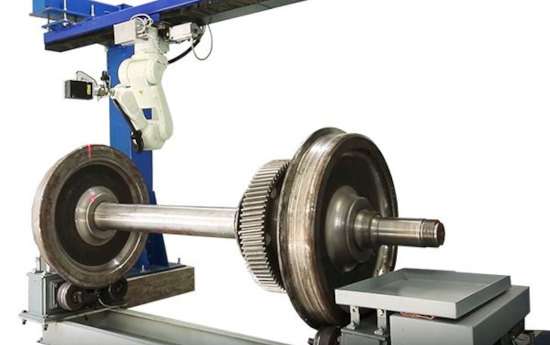

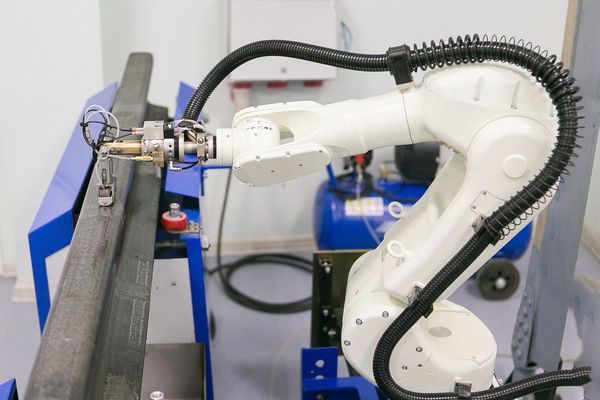

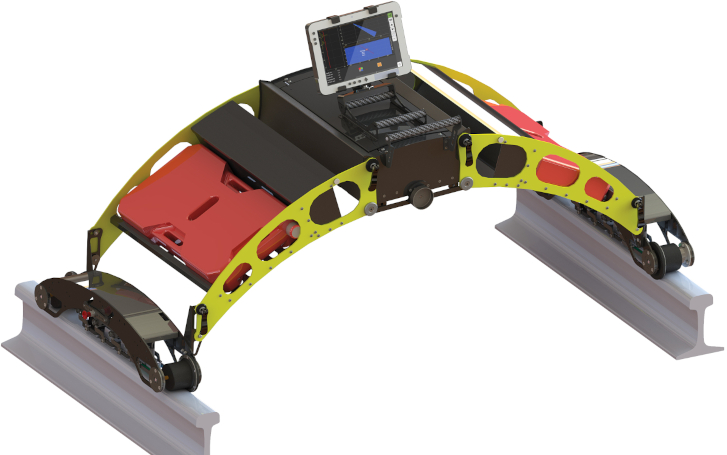

ROBOSKOP VTM-5000 KP

ROBOSKOP VTM-5000 KP Is applied for complex non-destructive testing of railway rolling stock (trams, subway cars, freight and passenger cars, motor-rolling stock) wheelsets. A flexible system of settings allows to make any test sequence while using both mandatory and auxiliary (confirming) NDT methods for selective test of individual zones.

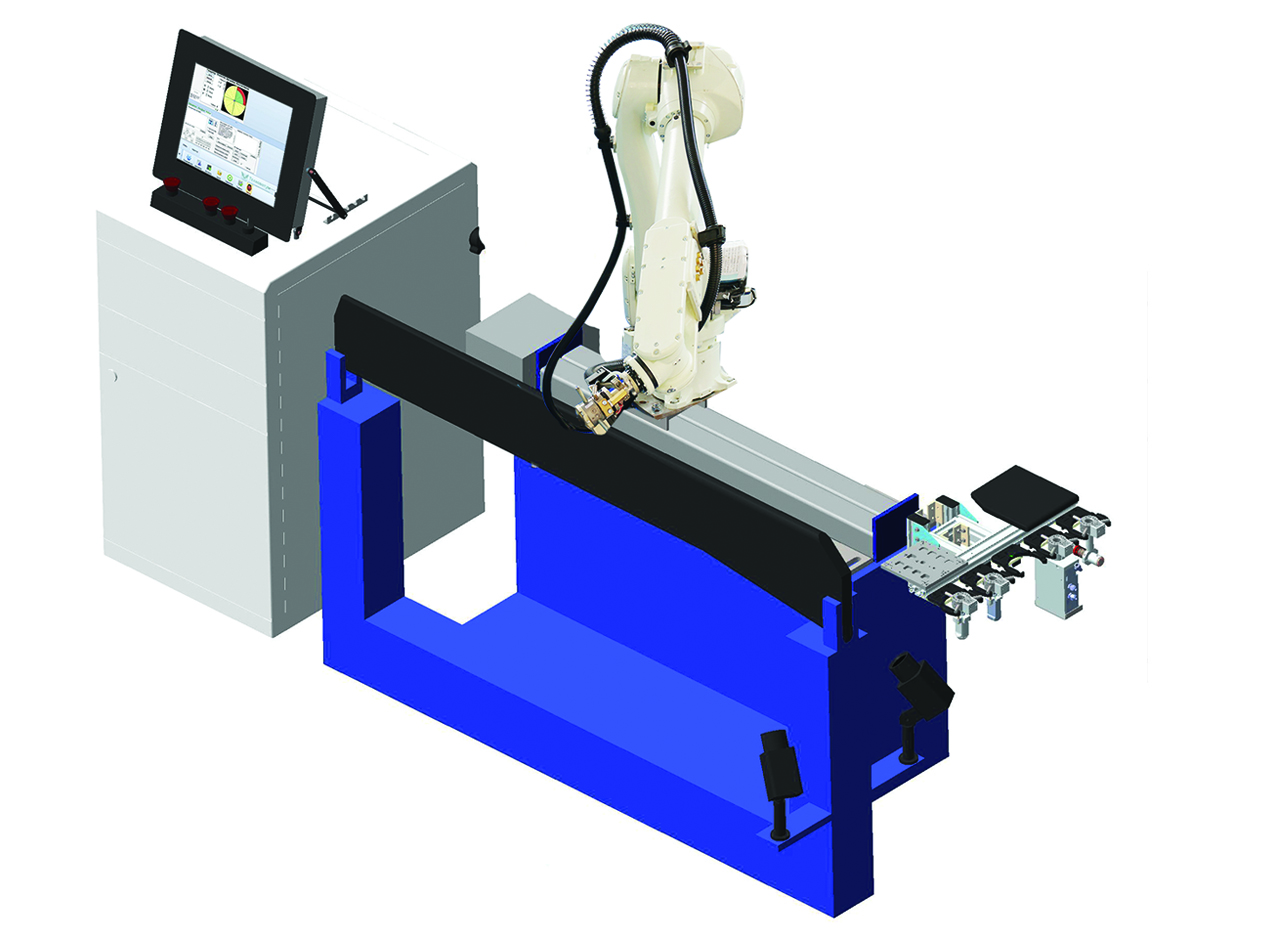

ROBOSKOP VTM-5000 RSP

The robotic complex ROBOSCOP VTM-5000/RSP is designed for nondestructive testing of welded rail joints in the technological flow of rail welding companies. ROBOSCOP VTM-5000/RSP manages laser geometric parameters measurementof railweld joint, hardness measurement, videomonitoring in the area of possible burn and ultrasonic testing over the entire rail section of the rail using phased arrays probes.

ROBOSKOP VTM-5000 OR

ROBOSCOP VTM-5000/OR - automated system of flaw-detection and laser measurement of wheel set axles of railway rolling stock: loco, carriage & wagon, motor driven rolling stock, metro-cars and trams. It is applied for conducting input and output non-destructive testing of railway axes during scheduled repairs. The ROBOSCOP VTM-5000/OR configuration settings and diagnostic methods selection take on account geometry changes and axes types, depending on their purpose.

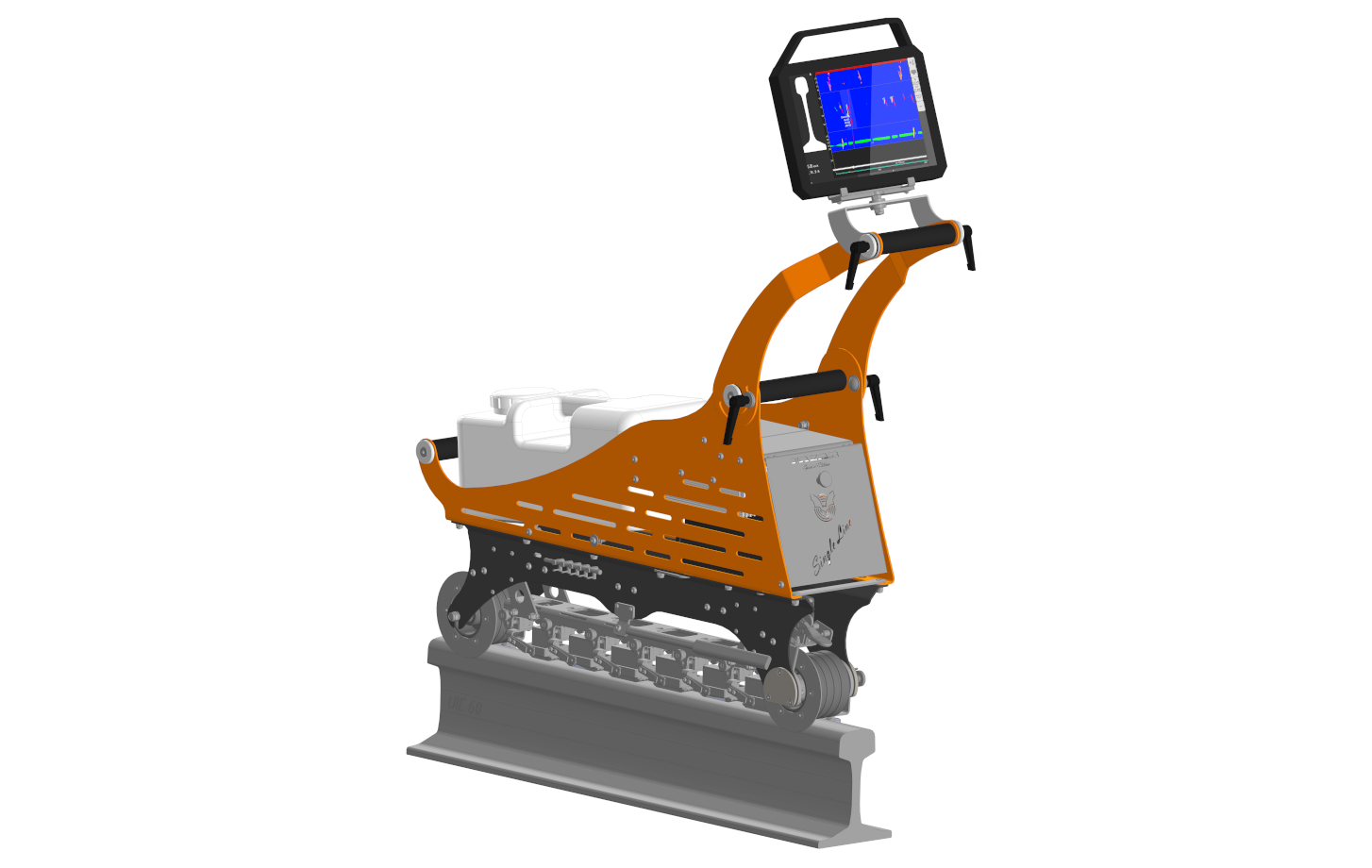

FAZAR 32+ (SL)

SINGLE-CUT RAIL ULTRASONIC PHASED ARRAY FLAW DETECTOR (PA) Single-line ultrasonic rail flaw detector on phased arrays (PAUT) for continuous ultrasonic testing of all types rail threads (R50, R65, R75, UIC52, UIC60, etc.) along the entire length and cross-section with decoding of defects, including testing of rail base blades.

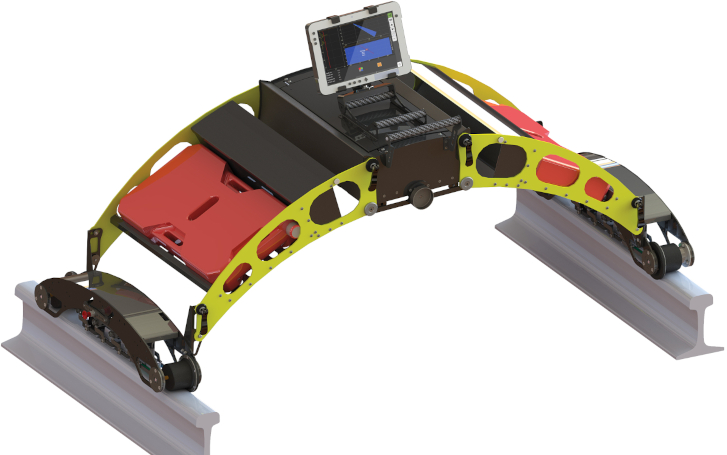

FAZAR 32+ (DL)

DUBLE-CUT RAIL ULTRASONIC PHASED ARRAY FLAW DETECTOR (PA) Double-line ultrasonic rail flaw detector on phased arrays (PAUT) for continuous ultrasonic testing of all types rail threads (R50, R65, R75, UIC52, UIC60, etc.) along the entire length and cross-section; rails turnouts with semi-automatic decoding of defects, including testing of rail base blades.

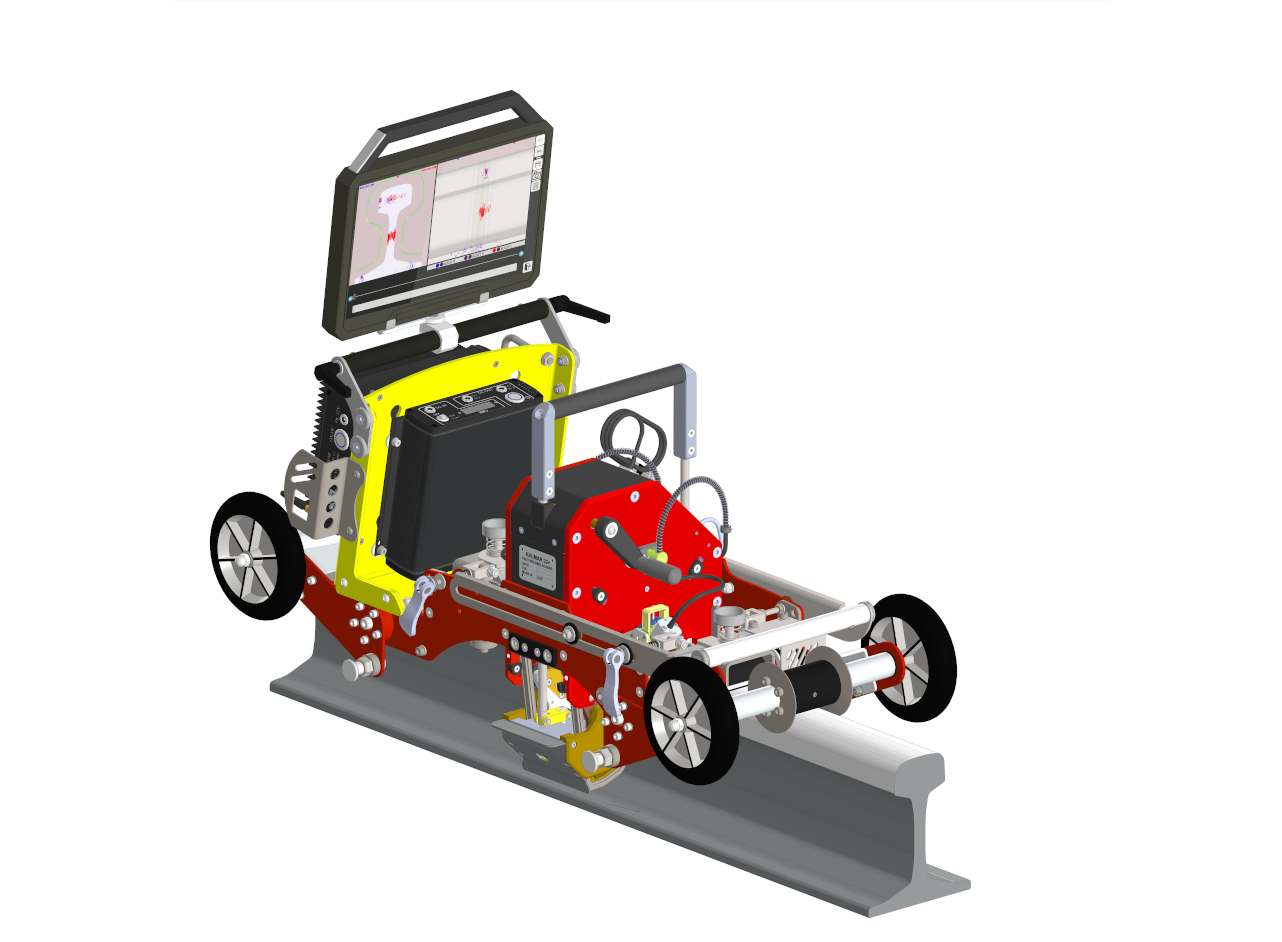

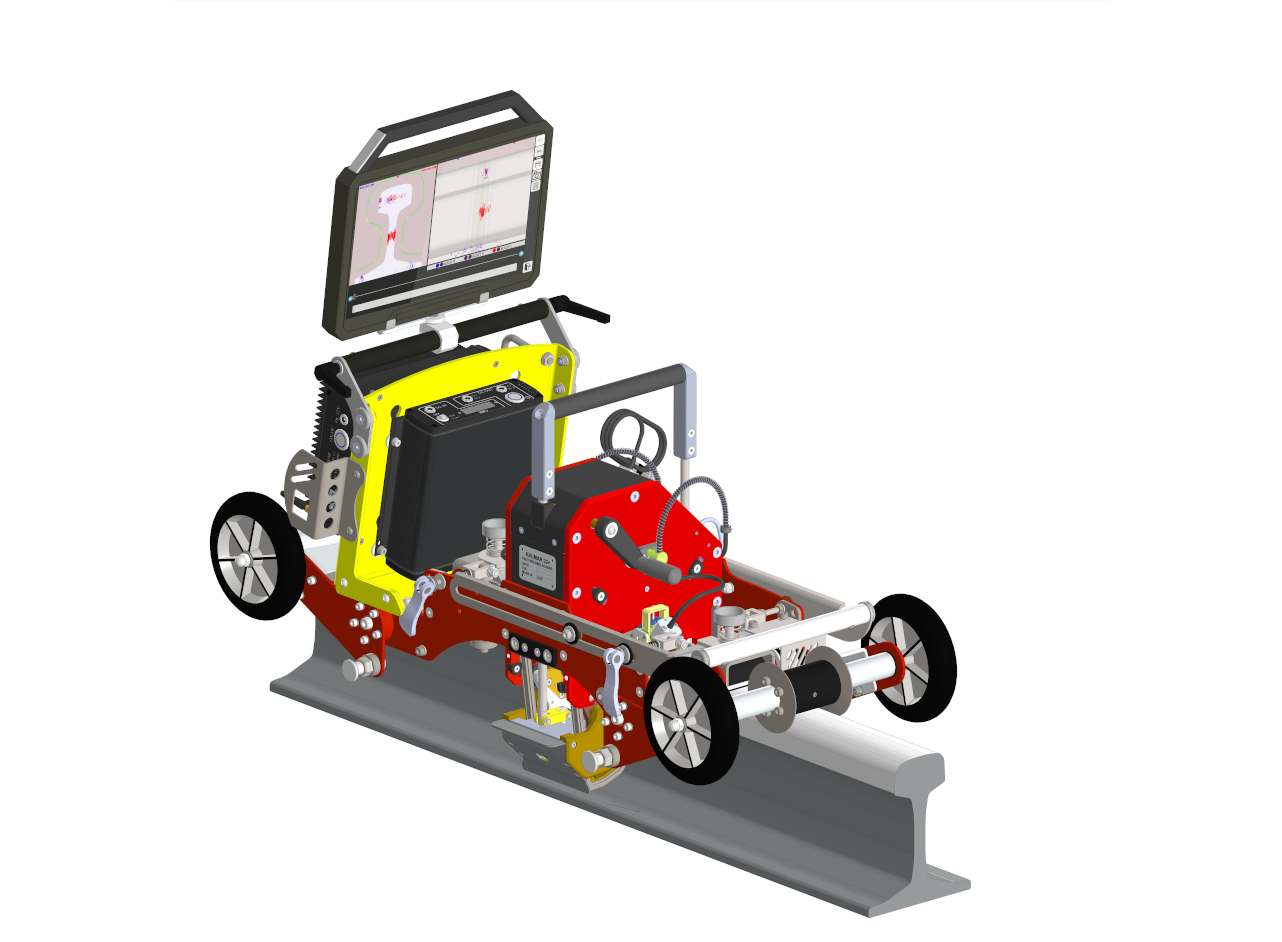

KALMAR 32+

MOBILE SINGLE-CUT RAILPHASED ARRAY FLAW DETECTOR (PA) Rail flaw detector with phased arrays for ultrasonic testing of welded joints of electric contact and aluminothermic rail welding (R50, R65, R75, UIC52, UIC60, etc.)

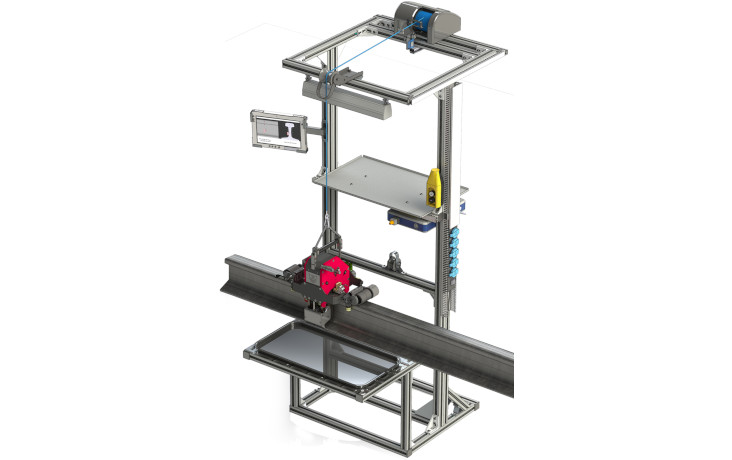

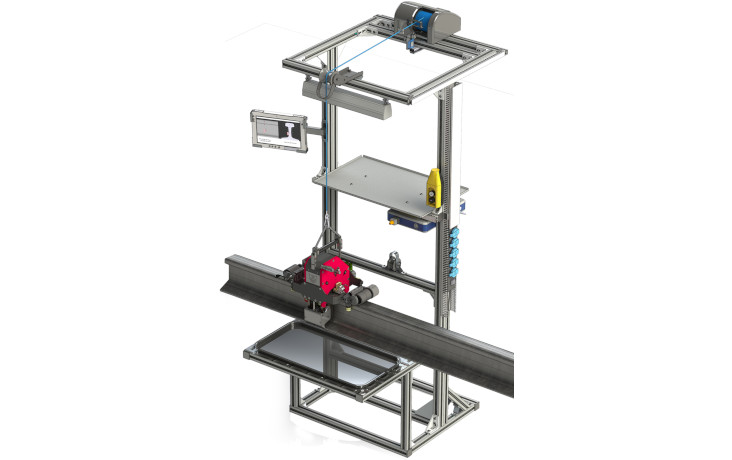

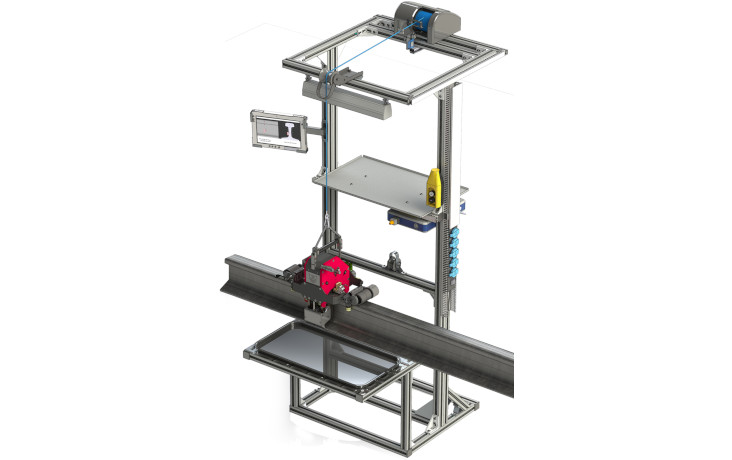

KALMAR 32+ RWE

STATIONARY RAIL FLAW DETECTOR ON PHASED ARRAY (PA) FOR RAIL WELDING ENTERPRISE (RWE) Designed for acceptance ultrasonic inspection of welded joints of electric contact welding of railway rails in the conditions of rail welding enterprises.

ROBOSKOP VTM-5000 AEROSPACE

The stend of laser scanning and flaw detection ROBOSKOP VTM-5000 AEROSPACE is designed for non-destructive testing of composite materials, honeycomb structures and heat-shielding coatings, used in the space industry.

ROBOSKOP VTM-5000 HELICOPTERS

The laser scanning and flaw detection bench ROBOSCOP VTM-5000 HELICOPTERS is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels It is also applicable in wind power engineering, small-sized shipbuilding, pipe fitting production, etc. All tooling (laser scanner, sensors) selection and change processes are automated.

ROBOSKOP VTM-5000 СOMPOSITE

The laser scanning and flaw detection bench ROBOSCOP VTM-5000/COMPOZITE is designed for the non-destructive testing of polymer-composite materials used in aircraft constructions: glider elements, helicopter blades, honeycomb panels It is also applicable in wind power engineering, small-sized shipbuilding, pipe fitting production, etc. All tooling (laser scanner, sensors) selection and change processes are automated.

ROBOSKOP VTM-5000 DISK

The laser scanning and flaw detection equipment ROBOSKOP VTM-5000 / DISK is designed for non-destructive testing of aircraft engine parts of various range by type and size. Typical test objects are aircraft blades, discs, various shafts and workpieces. ROBOSKOP VTM-5000 / DISK automatically performs operations with high accuracy of testing results and low test time.

BLENDING SCOPE WIZARD

WIZARD - blending scope for diagnostics and machining blades os aircraft engines. Blending scope is a set of assemblies and modules for diagnostics and service of blades of the aircraft engines and gas turbines. Milling module + Liquid penetrant modules in one case for multitask applications.

DAMI C-09

MECHANICAL IMPEDANCE ANALYSIS FLAW DETECTOR Is intended for detection of laminations, discontinuities, defects of lack-of-adhesion type and other continuity faults in multi-layer polymeric composite materials (PCM).

ROBOSKOP VTM-5000 KP

ROBOSKOP VTM-5000 KP Is applied for complex non-destructive testing of railway rolling stock (trams, subway cars, freight and passenger cars, motor-rolling stock) wheelsets. A flexible system of settings allows to make any test sequence while using both mandatory and auxiliary (confirming) NDT methods for selective test of individual zones.

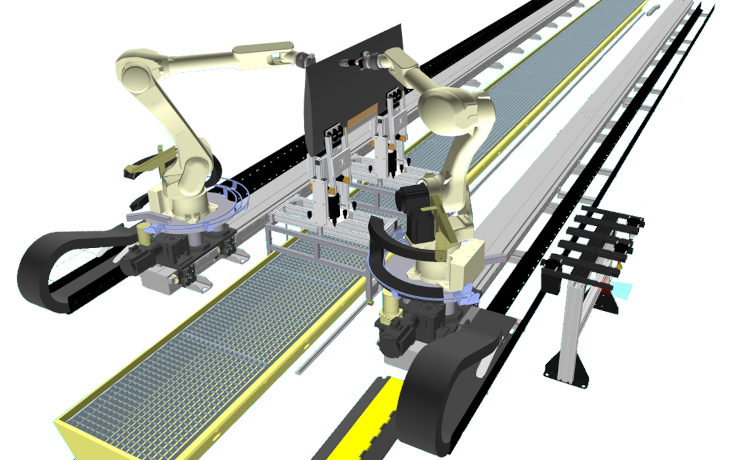

ROBOSKOP VTM-5000 RSP

The robotic complex ROBOSCOP VTM-5000/RSP is designed for nondestructive testing of welded rail joints in the technological flow of rail welding companies. ROBOSCOP VTM-5000/RSP manages laser geometric parameters measurementof railweld joint, hardness measurement, videomonitoring in the area of possible burn and ultrasonic testing over the entire rail section of the rail using phased arrays probes.

ROBOSKOP VTM-5000 OR

ROBOSCOP VTM-5000/OR - automated system of flaw-detection and laser measurement of wheel set axles of railway rolling stock: loco, carriage & wagon, motor driven rolling stock, metro-cars and trams. It is applied for conducting input and output non-destructive testing of railway axes during scheduled repairs. The ROBOSCOP VTM-5000/OR configuration settings and diagnostic methods selection take on account geometry changes and axes types, depending on their purpose.

FAZAR 32+ (SL)

SINGLE-CUT RAIL ULTRASONIC PHASED ARRAY FLAW DETECTOR (PA) Single-line ultrasonic rail flaw detector on phased arrays (PAUT) for continuous ultrasonic testing of all types rail threads (R50, R65, R75, UIC52, UIC60, etc.) along the entire length and cross-section with decoding of defects, including testing of rail base blades.

FAZAR 32+ (DL)

DUBLE-CUT RAIL ULTRASONIC PHASED ARRAY FLAW DETECTOR (PA) Double-line ultrasonic rail flaw detector on phased arrays (PAUT) for continuous ultrasonic testing of all types rail threads (R50, R65, R75, UIC52, UIC60, etc.) along the entire length and cross-section; rails turnouts with semi-automatic decoding of defects, including testing of rail base blades.

KALMAR 32+

MOBILE SINGLE-CUT RAILPHASED ARRAY FLAW DETECTOR (PA) Rail flaw detector with phased arrays for ultrasonic testing of welded joints of electric contact and aluminothermic rail welding (R50, R65, R75, UIC52, UIC60, etc.)

KALMAR 32+ RWE

STATIONARY RAIL FLAW DETECTOR ON PHASED ARRAY (PA) FOR RAIL WELDING ENTERPRISE (RWE) Designed for acceptance ultrasonic inspection of welded joints of electric contact welding of railway rails in the conditions of rail welding enterprises.

DAMI C-09

MECHANICAL IMPEDANCE ANALYSIS FLAW DETECTOR Is intended for detection of laminations, discontinuities, defects of lack-of-adhesion type and other continuity faults in multi-layer polymeric composite materials (PCM).

About us

Welcome to Pulsar, a pioneering force in the field of non-destructive testing (NDT) equipment and technologies. We specialize in NDT equipment and technology development, offering a wide array of inspection solutions, including advanced robotic units.

At Pulsar, we are not just manufacturers; we are creators. At the core of our mission is the development of science-based technologies and production of cutting-edge NDT solutions. We take immense pride in our world-class facilities, which include a dedicated training center, an advanced laboratory, and a technical diagnostics and service provision laboratories.

Through active participation in expert activities, we engage in dynamic partnerships with official and public organizations spanning diverse industries.

Our unwavering commitment to excellence is complemented by a strong desire to build lasting business relationships. We are constantly on the lookout for fresh opportunities to collaborate with new partners and drive innovation forward.